Press

11.10.2016 | CHEManager: PET composite keeps everything clear

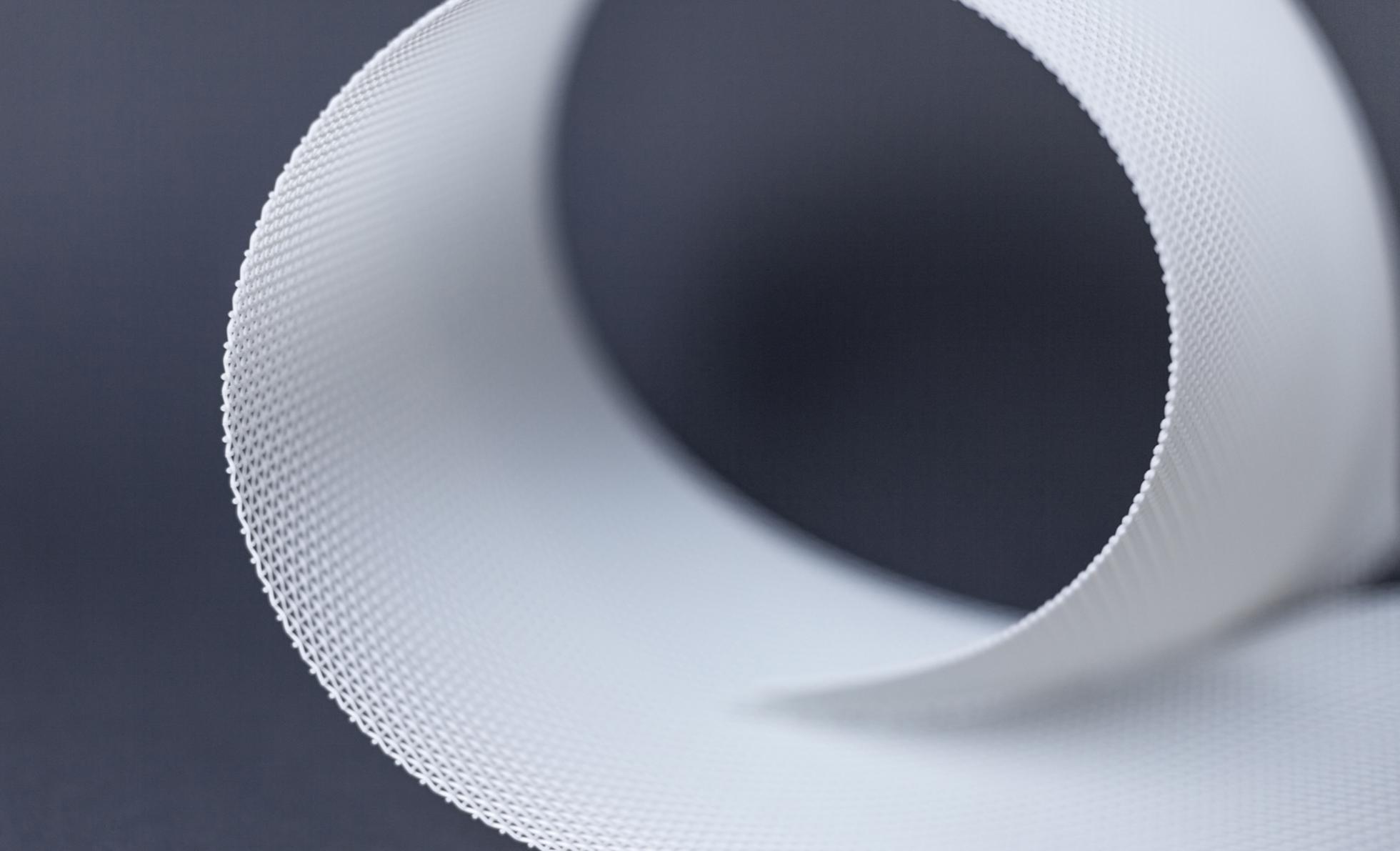

Heidland, Germany's largest manufacturer of filter belts for coolant water recycling, has reached a new dimension after commissioning a new PU edge coating machine and optimising the adhesive strength of PET laminated fabrics.

The major advantage of the filter materials made of laminated PET screen fabric used by Heidland is the high filtering performance (approx. 40 % higher flow rate compared with legacy filter fabrics) and with less pressure drop. Filtration precision is assured through the use of precise filter screens made of PET (30 – 150 μm).

The strength of the filter elements is achieved by the use of a coarse woven scrim fabric. Compared with common filter materials, such as double-layer woven fabric (DLW), the suspension can pass through the woven fabric barrier virtually unhindered, while the particulate matter is separated out in the filter screen at the surface of the filter material. Weaving the warp and weft in classical double-layer woven fabrics creates a chaotic arrangement of threads on the inside of the cloth; this prevents linear run-off of the fluids to a greater or lesser extent. Heidland's composite woven material combines excellent filtration performance with absolute filtration precision (Rau 160803).

The major advantage of the filter materials made of laminated PET screen fabric used by Heidland is the high filtering performance (approx. 40 % higher flow rate compared with legacy filter fabrics) and with less pressure drop. Filtration precision is assured through the use of precise filter screens made of PET (30 – 150 μm).

The strength of the filter elements is achieved by the use of a coarse woven scrim fabric. Compared with common filter materials, such as double-layer woven fabric (DLW), the suspension can pass through the woven fabric barrier virtually unhindered, while the particulate matter is separated out in the filter screen at the surface of the filter material. Weaving the warp and weft in classical double-layer woven fabrics creates a chaotic arrangement of threads on the inside of the cloth; this prevents linear run-off of the fluids to a greater or lesser extent. Heidland's composite woven material combines excellent filtration performance with absolute filtration precision (Rau 160803).