News

Overview

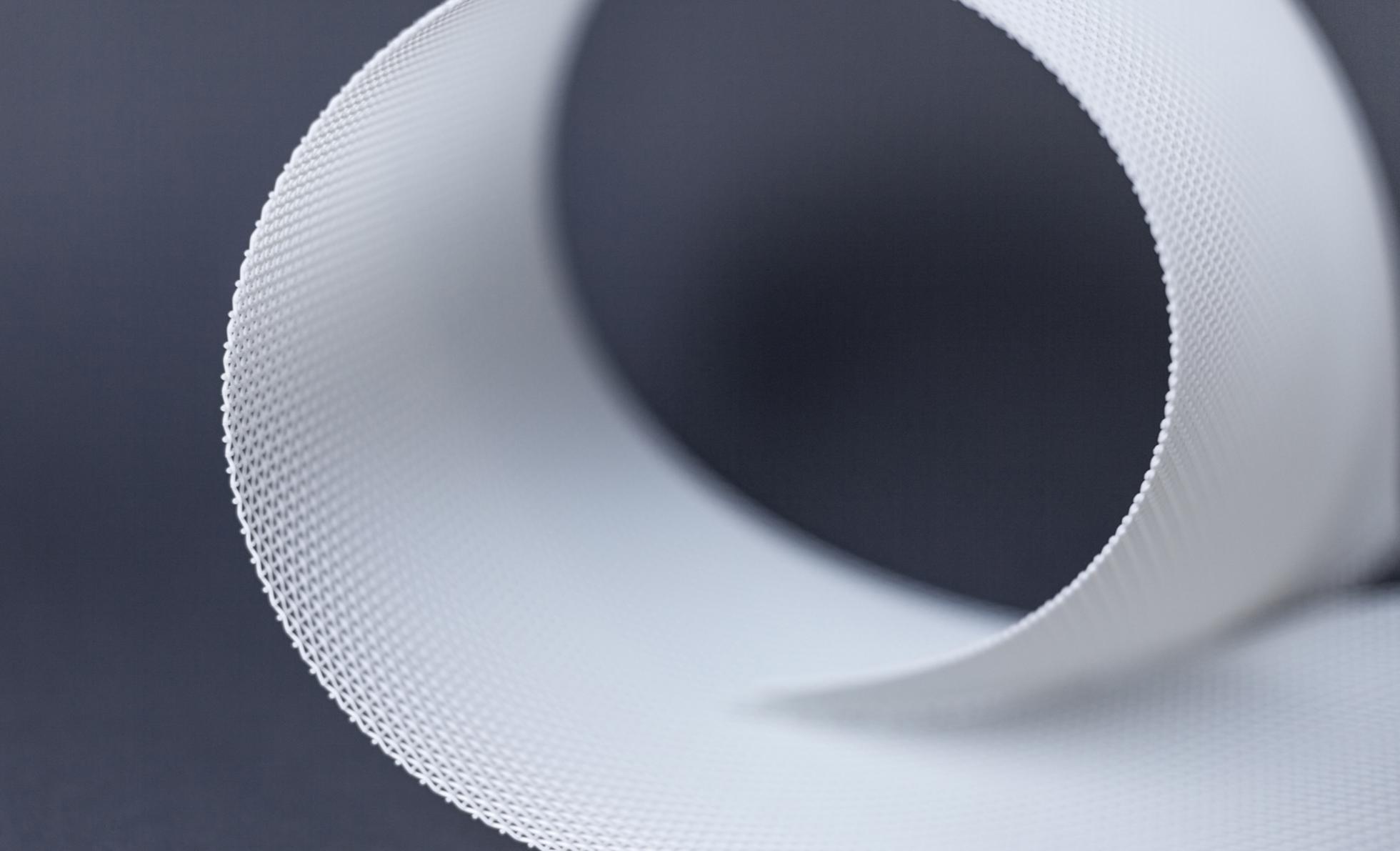

03.2024 | The new TPU-closure

• easiest handling

• over-/or underlapping not required

• securing with special retaining brackets

• enormous flexibility

• also suitable for small roll diameters

• significant time savings during assembly

• high chemical resistance e.g. compared to cooling lubricants

• low material build-up

• additional assembly tools not needed

• pintle wire not necessary

• further sealing not required

• over-/or underlapping not required

• securing with special retaining brackets

• enormous flexibility

• also suitable for small roll diameters

• significant time savings during assembly

• high chemical resistance e.g. compared to cooling lubricants

• low material build-up

• additional assembly tools not needed

• pintle wire not necessary

• further sealing not required

product-flyer as PDF

For further information, please contact us.

07.2023 | Employees wanted!

In the field of technical fabric confection, we are looking for employees (m/f/d) in full-time or part-time starting from August 1st, 2023!

Your tasks:

Sewing, cutting, processing of technical fabrics

Precise measuring and packaging

What awaits you:

Competitive salary

Please send your application documents exclusively in written form by mail or, if preferred, via email to: altas@heidland-gewebe.de.

Vacation and Christmas bonus

30 days of vacation

Good working atmosphere and a friendly team.

Please send your application documents exclusively in written form by mail or, if preferred, via email to: altas@heidland-gewebe.de.

Your tasks:

Sewing, cutting, processing of technical fabrics

Precise measuring and packaging

What awaits you:

Competitive salary

Please send your application documents exclusively in written form by mail or, if preferred, via email to: altas@heidland-gewebe.de.

Vacation and Christmas bonus

30 days of vacation

Good working atmosphere and a friendly team.

Please send your application documents exclusively in written form by mail or, if preferred, via email to: altas@heidland-gewebe.de.

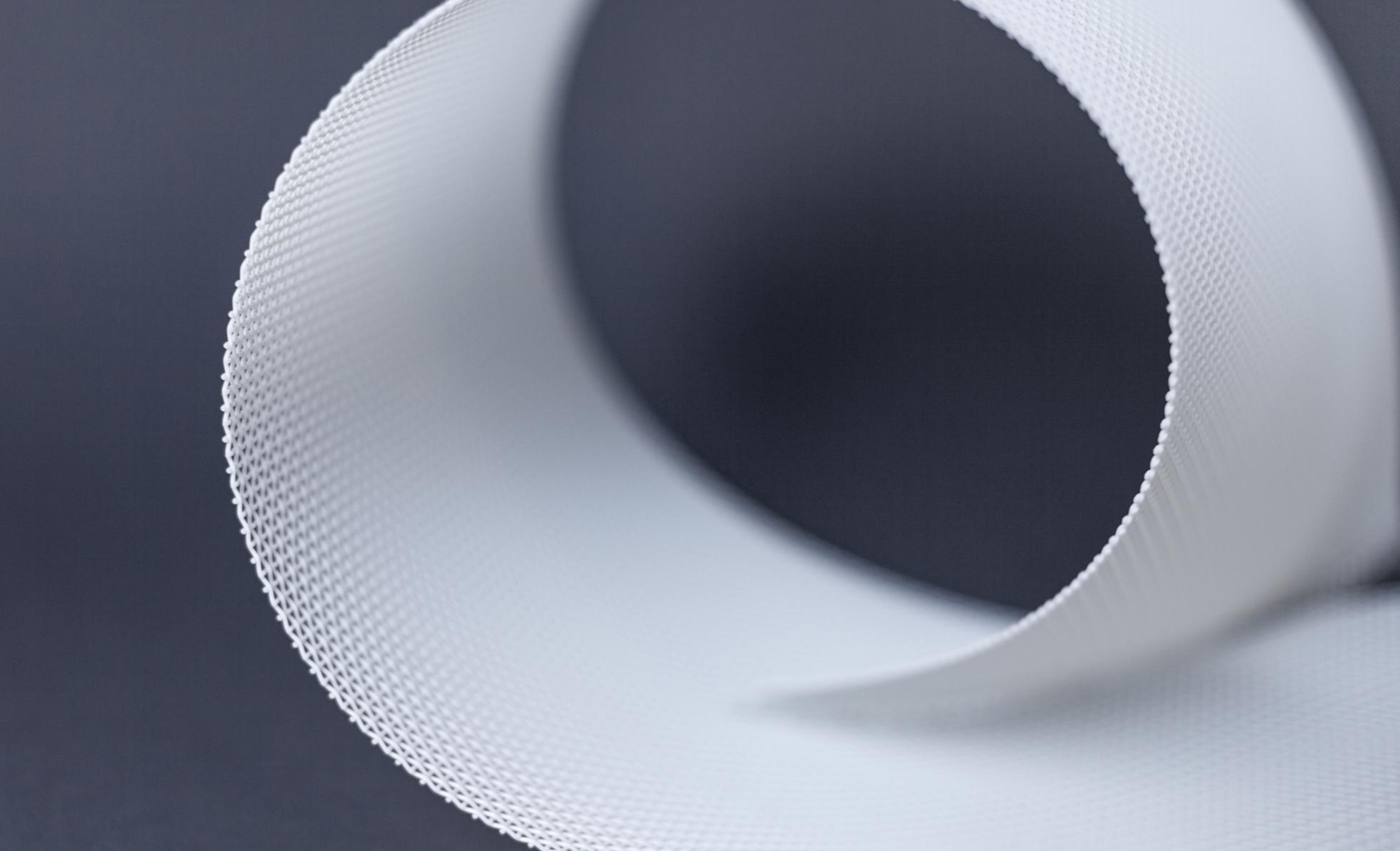

05.2023 | Customized Manufacturing

Cast-on toothed belts and/or row of bolts for stable belt guidance.

03.2023 | Honors for long-time employees

Mutual respect and appreciation leads to joint success. Acting according to this maxim, we are very fortunate to have a top team in administration and production. The highest asset of an entrepreneur are his employees.

We, the management of Heidland GmbH & Co. KG, would like to take this opportunity to thank Mrs. Claudia Zahn and Mrs. Monika Elfenkemper for 20 years of service.

We would like to take this opportunity to wish our employees all the best for the future, good health and hopefully many more years of successful cooperation in our team.

Bernd Röttgers and Dipl.-Ing. (FH) Guido Rauße

Managing partners

We, the management of Heidland GmbH & Co. KG, would like to take this opportunity to thank Mrs. Claudia Zahn and Mrs. Monika Elfenkemper for 20 years of service.

We would like to take this opportunity to wish our employees all the best for the future, good health and hopefully many more years of successful cooperation in our team.

Bernd Röttgers and Dipl.-Ing. (FH) Guido Rauße

Managing partners

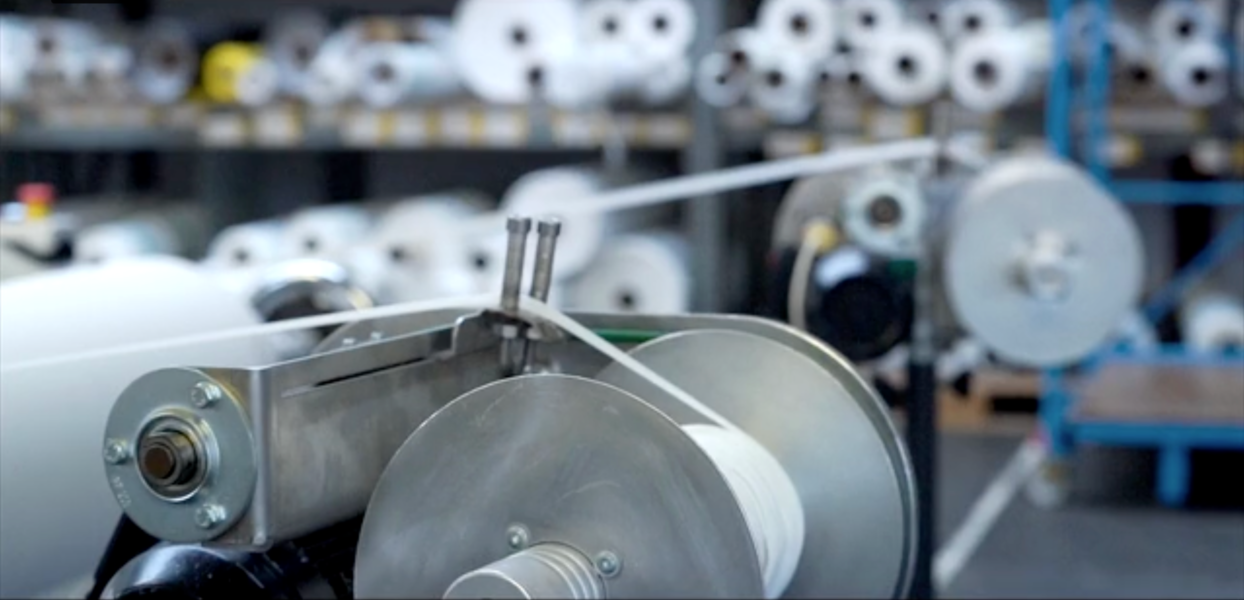

02.2023 | Heidland-Image-Video

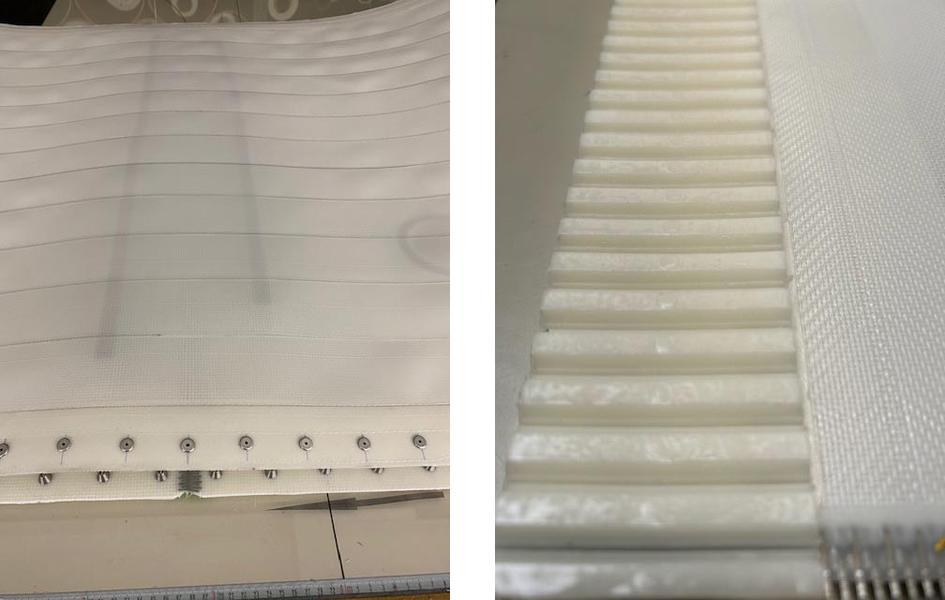

12.2022 | Composite Filter 4.0

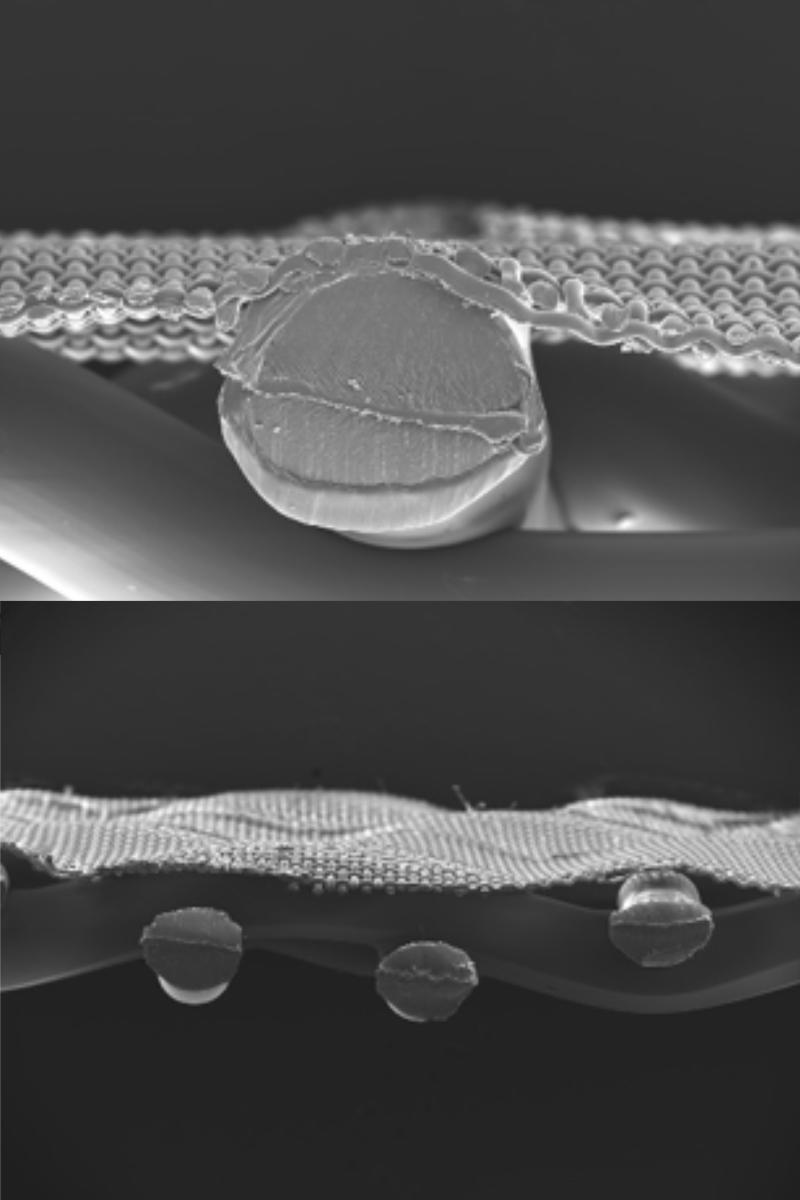

Increasing challenges to the filtering process have led us to think about a groundbreaking innovation in the design of composite filters made of a fine fabric (filter) and a coarse fabric (supporting fabric).

While in the past ordinary double-layer filter media were woven and later point-glued, we make use of a relatively new technology from the yarn industry. The carrier fabric is partly made of so-called core-jacket yarns.

The fine mesh is connected to the coarse mesh under pressure and temperature. The coat of individual yarns in the supporting fabric melts and the liquid plastic combines with the upper cover layer of fine fabric when it catches a cold.

This has enormous advantages for the filtering process:

– fully renewable

– improved chemical resistance

– higher throughput capacity

– smallest filter fineness possible

– material 100% sorted

– can be used in the food industry.

10.2022 | Filtech 2023

At this point we would like to inform you that we will be exhibiting again next year at the Filtech in Cologne. We look forward to your visit at our booth. You can expect some interesting new developments in the field of cooling lubricant regeneration. In addition, we will also present the wide range of our possibilities.

Sincerely yours

Dipl.-Ing. (FH) Guido Rauße

Managing Partner

Sincerely yours

Dipl.-Ing. (FH) Guido Rauße

Managing Partner

03.2022 | Impressions from the Filtech 2022

03.2022 | Heidland at the Filtech 2022

03.2022 | Product-availability without restrictions

Dear customers,

due to the current events in Ukraine, we would like to inform you that, according to the current state of knowledge, delivery bottlenecks are not to be expected from our side.

We do not have trade relations with suppliers from Russia. Our supply chains are optimized to the extent that we receive almost 95% of our raw materials from suppliers in Germany or neighbouring countries.

Through long-term contracts with our suppliers, we constantly try to ensure our supply of raw materials.

In the event of a foreseeable supply bottleneck, we will of course inform you in good time. Currently, your products are available without restriction.

due to the current events in Ukraine, we would like to inform you that, according to the current state of knowledge, delivery bottlenecks are not to be expected from our side.

We do not have trade relations with suppliers from Russia. Our supply chains are optimized to the extent that we receive almost 95% of our raw materials from suppliers in Germany or neighbouring countries.

Through long-term contracts with our suppliers, we constantly try to ensure our supply of raw materials.

In the event of a foreseeable supply bottleneck, we will of course inform you in good time. Currently, your products are available without restriction.

03.2022 | Filtech 2022

We will again exibit at the Filtech trade fair in Cologne from march 8 to 10th 2022.

12.2021 | Dry Pasta

At this point we would like to inform you about an expansion of our product range. We manufacture dryer belts for pasta production from a specially adapted polyester fabric for use in the food sector (see photo). Fabric 1000-44 is suitable for ambient temperatures of approx. 100 °C with up to 70 % humidity. The fabric edges are bordered with fabric tape to protect against mechanical damage. If you have any further questions, please do not hesitate to contact us at info@heidland-gewebe.de or +49 2588 935420.

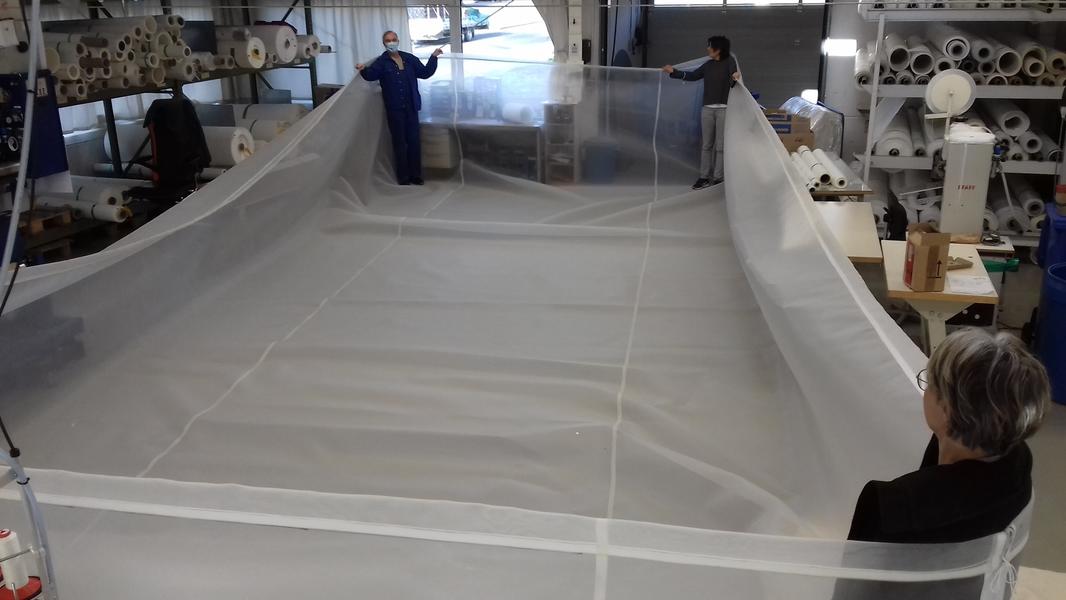

02.2021 | Farming Net MO 1000 µm

Nets made of special fabric for fish farming

We assemble the very soft and extremely stable sieve mesh into holding nets. The lengths of fabric are cut and sewn in complex manual work. Some of the materials can be welded. Our nets are used in fish farming for keeping or for the targeted rearing of smaller fish. Depending on the mesh size of the screen mesh, different fish and / or crab sizes up to the egg can be held. In case of need, please contact us: 02588 935420 or info@heidland-gewebe.de

We assemble the very soft and extremely stable sieve mesh into holding nets. The lengths of fabric are cut and sewn in complex manual work. Some of the materials can be welded. Our nets are used in fish farming for keeping or for the targeted rearing of smaller fish. Depending on the mesh size of the screen mesh, different fish and / or crab sizes up to the egg can be held. In case of need, please contact us: 02588 935420 or info@heidland-gewebe.de

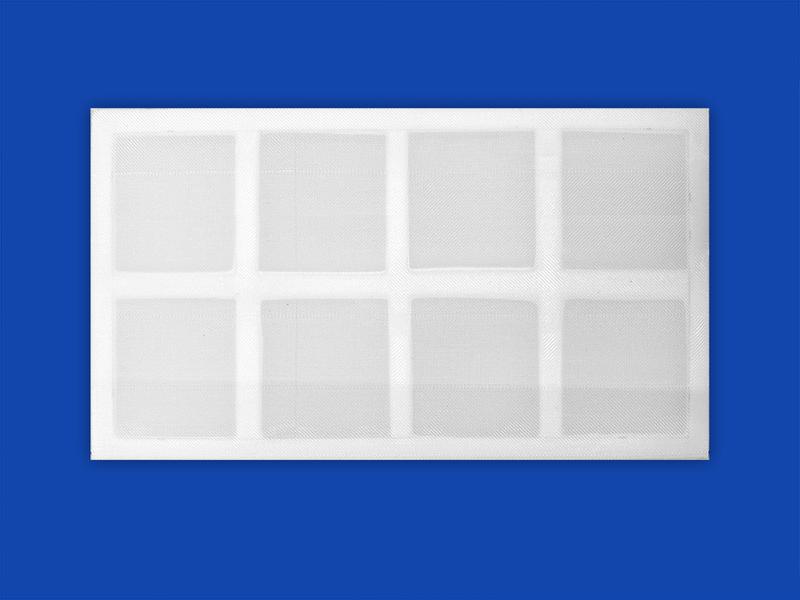

11.2020 | We provide clarity

Discontinuous plate pressure filters are used in various industries. The included plate packages usually also consist of stainless-steel plates, with a coarse support fabric as carrier material and a fine steel sieve as the actual filter fabric material. The filter cake forms on the surface of the fine tissue and the filtrate flows through the central collection tube.

Heidland GmbH & Co. KG manufactures the plate filter rounds from special laminated polyester fabric. The polyester fabric is characterized by an absolute power of separation with maximum permeability. The fabric is available in mesh sizes from 30 to 150 microns. Particularly advantageous are the significantly lower production costs compared to conventional stainless-steel plates. The steel body of the filter rendis can also be reused.

Different diameters of the filter rounds and the varying number of rounds per plate filter package are realized according to the customer's requirements.

Heidland GmbH & Co. KG manufactures the plate filter rounds from special laminated polyester fabric. The polyester fabric is characterized by an absolute power of separation with maximum permeability. The fabric is available in mesh sizes from 30 to 150 microns. Particularly advantageous are the significantly lower production costs compared to conventional stainless-steel plates. The steel body of the filter rendis can also be reused.

Different diameters of the filter rounds and the varying number of rounds per plate filter package are realized according to the customer's requirements.

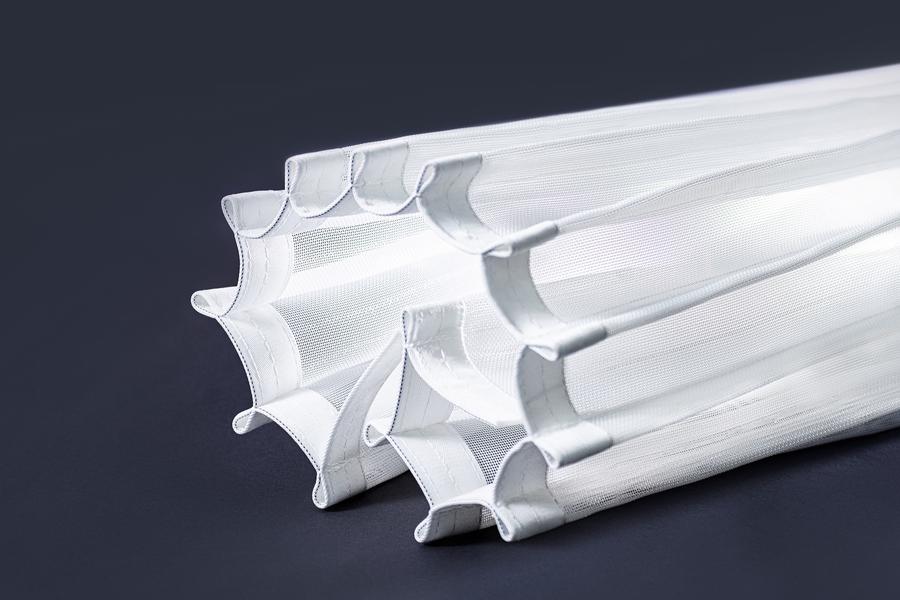

11.2020 | Filter segments for drum filters

Heidland GmbH & Co. KG has been manufacturing filter segments for drum filters for quite some time (see photo). A laminated polyester filter fabric with mesh sizes of 30 to 150 microns is used as a filter material. The segments are framed with a high-strength and at the same time very flexible PU. The filter segments are manufactured user-specific (e. g. width and thickness of the frames). We also manufacture individual segments for test series. If necessary, please contact us.